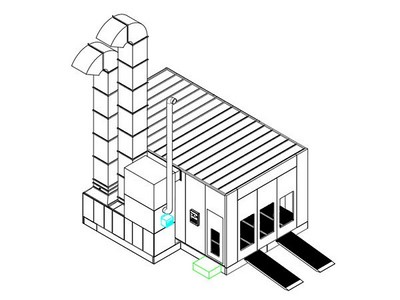

The size of every paint booth is custom manufactured to accommodate your installation site, budget and product being painted.

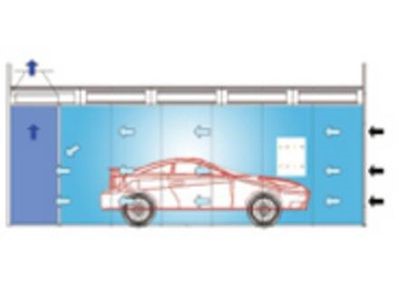

Before starting the production of paint booth, we design an effective airflow style to dry painted surfaces rapidly, avoiding negative pressure and dead air spaces caused by high filter resistance that can impact the painting effect.

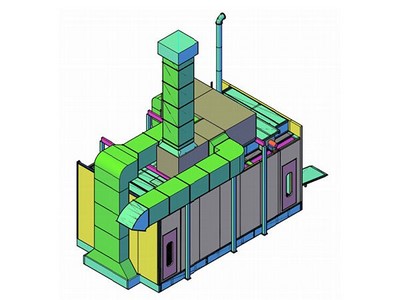

Full downdraft

Full downdraft

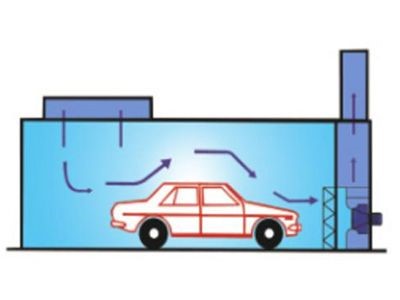

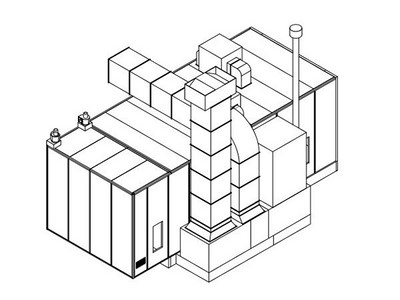

Semi-downdraft

Semi-downdraft

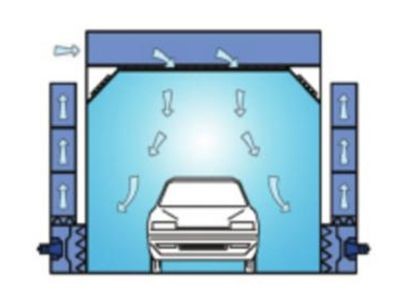

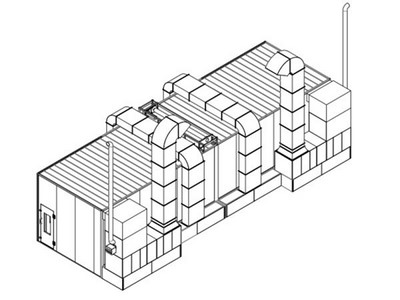

Side downdraft

Side downdraft

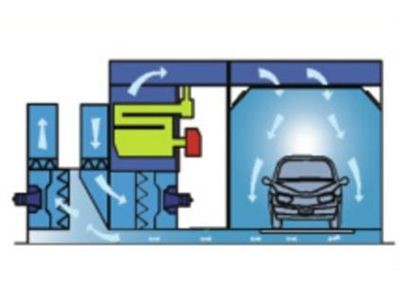

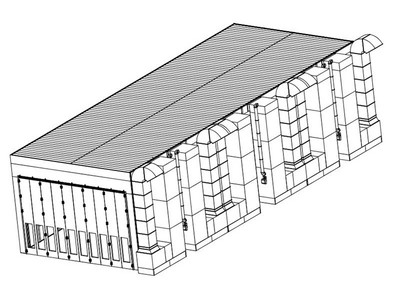

Crossdraft

Crossdraft

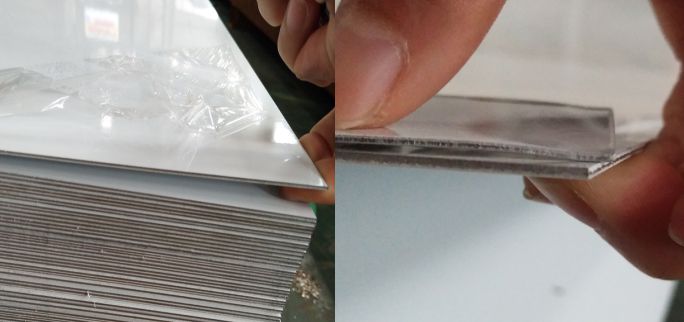

We offer sheet metal with thickness options of 0.326mm, 0.426mm, 0.6mm, 0.9mm to meet specific demands on rigidity and strength of wall panels.

Machine-made wall panel

Machine-made wall panel

Manual-made wall panel

Manual-made wall panel

Our wall panels are manufactured utilizing Italian automatic wall panel production line, featuring high precision and durability. All wall panels are double edge banded for superior look, and male & female clip-in system allows easy assembly of panels while ensuring perfect joining.

On the basis of common oil-based paint booth, we adopt air acceleration system to speed up the drying time of waterborne and solvent-based paints and to increase the productivity. Waterborne paint booth is equipped with four 0.75kw centrifugal fans to enable the hot air flowing at a higher velocity over the vehicle. As it turns out, the water is evaporated quickly from the surface of the painted times, thus accelerating the drying process while providing smooth paint surface.

1. Ceiling mounted air acceleration system

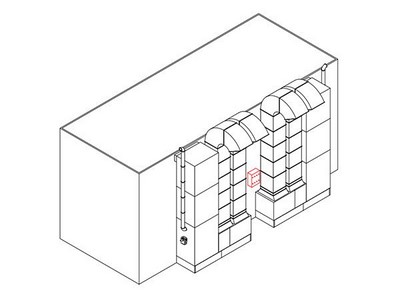

The air acceleration system features air nozzles which are laid at a 45 degree angle on both sides inside the booth, enabling the heat to be distributed evenly over the vehicle. The uniform balance of air ventilation is guaranteed by adding two sets of air ducts placed below the upper lights on both sides, each set of duct has 20 vents and every 10 vents have a centrifugal fan.

Ceiling mounted air acceleration system integrates light box, light fixtures and air duct, the blowers are mounted at ceiling plenum.

Ceiling mounted air acceleration system integrates light box, light fixtures and air duct, the blowers are mounted at ceiling plenum.

Installation at a 45 degree angle on both sides of the booth

Installation at a 45 degree angle on both sides of the booth

Stainless steel air nozzles

Stainless steel air nozzles

2. Corner mounted blowers with light fixture

3. Corner mounted blowers without light fixture

EPS

EPS

Rockwool

Rockwool

We offer two options of insulation materials, i.e. EPS and rockwool, you can choose the insulation materials according to your budget or local standard. Rockwool has better thermal insulation performance.

English

English français

français русский

русский فارسی

فارسی español

español português

português العربية

العربية Indonesia

Indonesia Česky

Česky românesc

românesc български

български

IPv6 network supported

IPv6 network supported